Our services

Everything from one source

With our many years of experience, we provide our customers with intensive support right from the project and prototype phase. Through close cooperation with the development departments, the optimal manufacturing steps for the upcoming production are discussed early in the development process.

In this way, the components can be optimized in terms of process reliability and the exact customer requirements. In the case of an order, we thus create a smooth process flow and can also improve the quality of the components.

Our business partners are well-known companies from all industries, including electronics, IT, computers, embedded computers, drive technology, ventilation and air-conditioning technology, energy supply and solar technology, medical technology as well as advertising and design.

Our services

Your advantages with EM Gerätebau

- Material processing: We process steel, galvanized steel, stainless steel, aluminum, copper and much more, with a sheet thickness of 0.1 to a maximum of five millimeters.

- Peoduction spectrum: Whether batch size 1 or series production, everything is possible with us.

- Everything from a single source: From technical advice to delivery to the factory, we are your competent advisor on all aspects of sheet metal processing.

make contact

Ahornstraße 8 – 14

82291 Mammendorf

Germany

Montag bis Freitag

08:00 bis 18:00 Uhr

Our services

Scope of services

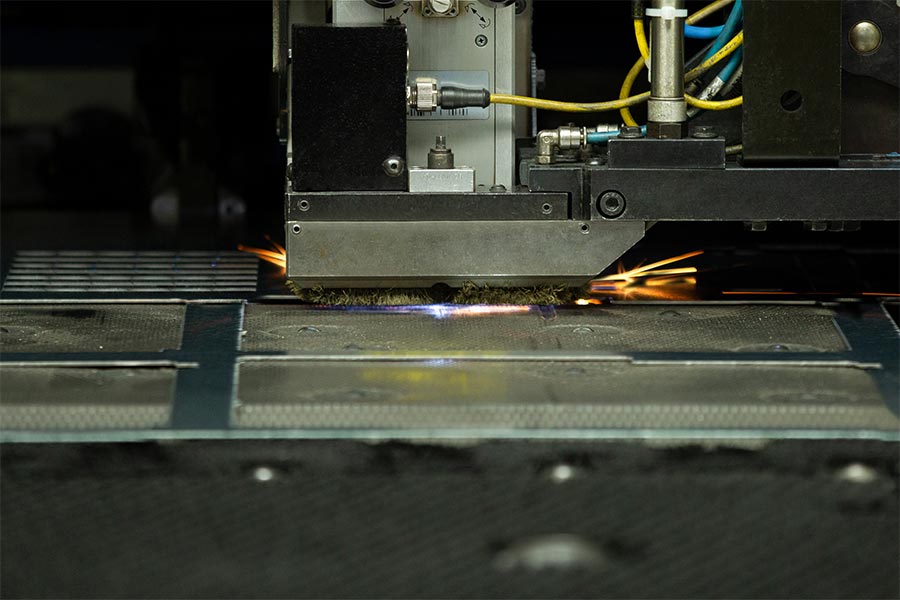

Punching and lasering

Our production in the area of punching and lasering works exclusively with machines from the world market leader TRUMPF. The production of samples or small series is carried out in manned shifts. For series production, our focus is on a high degree of automation. Process precision lays the foundation for all subsequent processes.

Our production processes and structures are subject to ongoing analysis. Targeted investments in new technologies ensure successful further development in line with requirements.

Deburring, straightening and cleaning

Straightening, deburring and cleaning are carried out for all parts using a standardized process in our production facility.

This ensures a consistently high quality of the cut for all subsequent processes.

Deburring is carried out in-house using highly efficient lamella deburring machines.

Bending and edging

Thanks to our state-of-the-art machinery and various machine sizes, we can offer you a wide range of bent parts and produce them on time.

The use of a fully automated bending cell guarantees efficient production of parts in consistent quality at high volumes. The integrated sheet thickness measurement ensures the precise production of the bent parts.

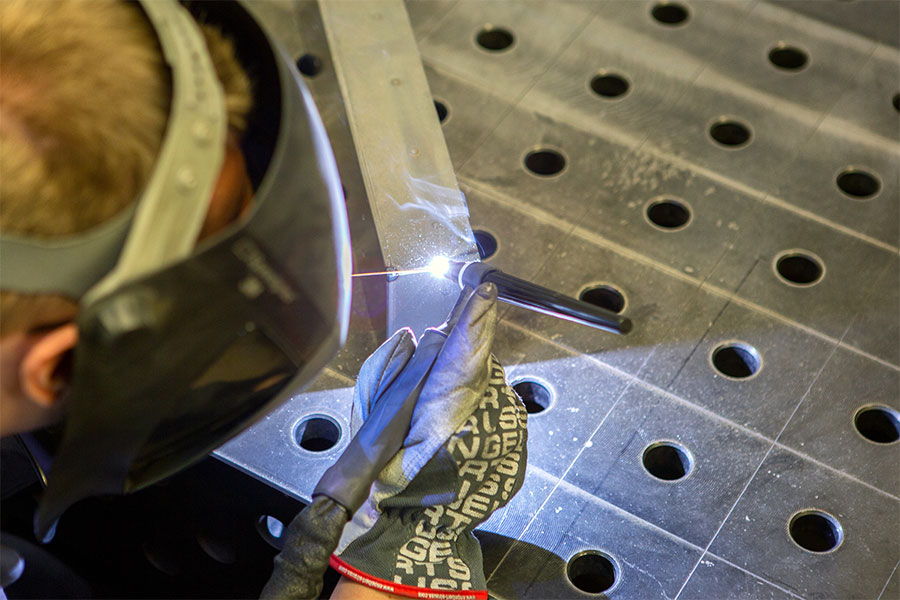

Welding

The processes we use include TIG (tungsten inert gas) welding, spot welding and stud welding.

We will be happy to advise you on welding capabilities for a wide variety of materials and the workpieces to be processed.

Mechanical Machining

Complementing our laser, punching and bending services, we provide mechanical machining of parts.

This is particularly useful for complex work that cannot be performed on the machines in the individual areas (punching, lasering and bending).

Surface technology

With our in-house powder coating, we not only process parts manufactured by us – we are also your competent contact if you require powder coating of finished parts.

We take care of chemical or galvanic coating of surfaces, as well as printing and labeling for you.